(27 compact 480x360 pics loading)

JUNE 2 2004

updated more pics 8-9-2004

wording improved 1-15-2005

answer = NO

Introduction: It seems to be a popular rumor that 571 is so much weaker than 410 with particular references to the pinion tooth count. It needs to be pointed out that it's not the pinion teeth that break....it's the ring gear that blows first....that it's a "don't care" if the pinion has 7,8,9,10 or 11 teeth. That said, if it's the ring gear that loose teeth first then it's just a matter of comparing the 2 rings to determine which is over-all stronger......

410 ring.....41 teeth on a 7.89" diameter.

571 ring.....40 teeth on the same diameter.(bigger tooth)

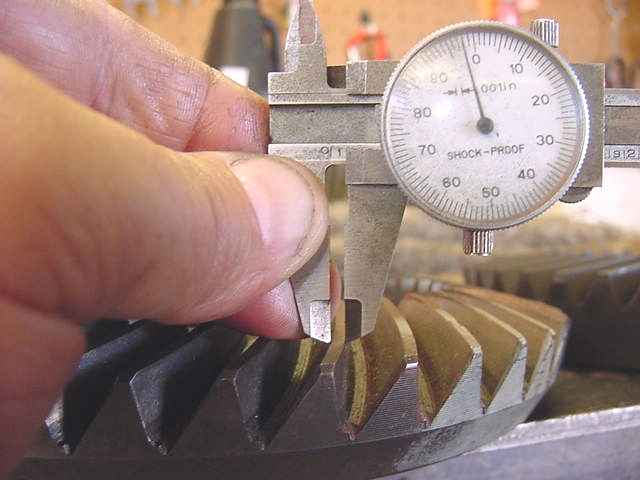

ring gear thickness:

410 on the left(girly).

571 on right(extremely rigid).

Length of 410 tooth 1.428"

571 length 1.394"(1 spark plug gap smaller)

root of tooth.....410 is about .500"

571 is measured the same

Top of tooth....410 is a wimpy .098"

571 is robust at .138"

ok to draw your own conclusion now.

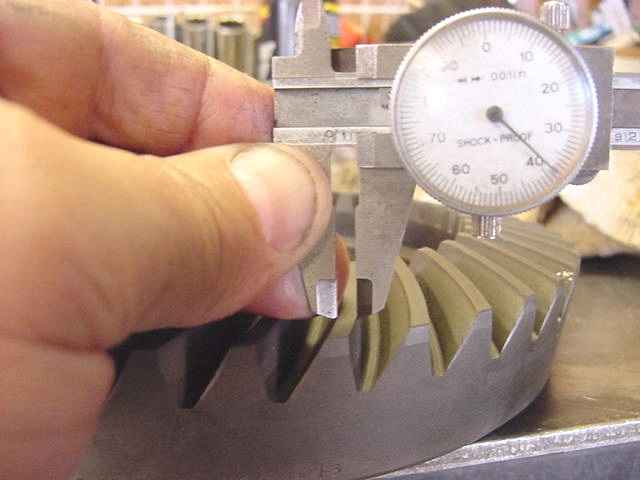

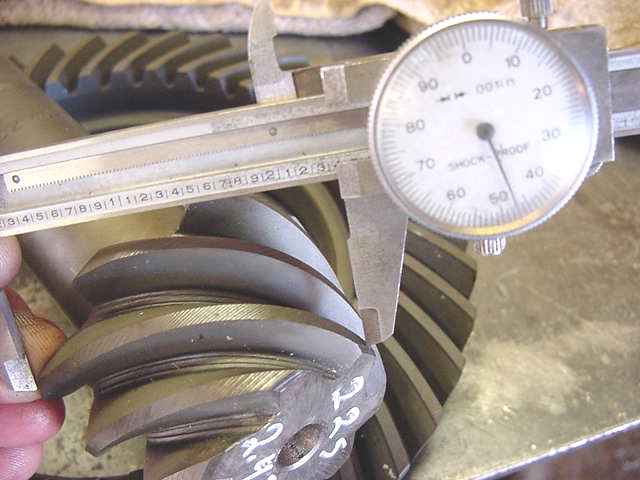

--some pinion notes--

410 is a long 2.630 about.

571 is a good 2.350" about.

410

571

--some more notes--

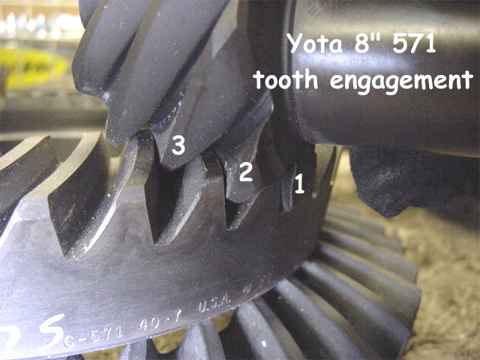

After consulting with a major gear manufacturer in the USA, we received an email from the engineering department quoting "ANY AND ALL SPIRAL BEVEL GEARS HAVE MORE THAN ONE TOOTH TOUCHING AT ALL TIMES WHEN DRIVING THE RING GEAR". We tested that and lined up the Toyota 410 mesh by eyeball and we discovered we could get 3 teeth in contact at the same time. As shown above, tooth #1 just started making contact on the heel.....#2 was making solid contact in the middle and #3 was getting ready to leave the toe end.

Then we did the same test with a 571 gearset expecting less contact but much to our surprise, we also had 3 teeth making contact.....hmmm.

So to broaden our comparisons, crashinaz brought over a variety of quality Dana gears. Tooth #1 just started making contact on the heel (outer) end of the ring on this dana 410 set.

A quick look on the other side of the pinion shows #3 tooth is getting ready to leave the toe (inner) side.....that's 3 teeth making contact.

We repeated that with a Dana 373 and same thing.....3 teeth.

Repeated the test with a brand new 6.17 Dana set.....

....and same thing, found that 3 teeth made contact.

Here's a comparison of 3 different Dana ratios. That 617 pinion sure looks tiny.....but we noticed the actual tooth size was BIGGER on the 617 pinion. See pic below.

Just for fun, here's a comparison of Dana to Yota....

Above is a Yota 8" ring gear.....

...and the smaller IFS 7.5" Yota ring.

Tooth Contact Pressure (TCP)

As the numeric gear ratio goes up so does the TCP. A 571 is about 40% geared lower than a 410.....as such, the 571 ring may see up to 40% greater TCP. 571 gears are high performance gears by their very numbers. A 410 is a low performance gear ratio and is more suited for road races. :)

So now there's a very small trend to step DOWN to a 410 thinking that somehow this gearset is stronger for the extreme riggers of boulder crawlin'. But then it is discovered that clutches start smelling and the engine seems to stall out all the time and so to make up for the lower 410 performance additional gearing is put elsewhere in the form of double cases or Marlin gears. This now puts additional torque strains on the driveshaft and its u-joints as well as the 410 gearset. And the 410, with its over-all enemic RING.... then goes Kaboom. If this link works it makes the point..... HERE

So why the bad rap for 529/571 ratios? Well, for one thing, this is the internet and rumors tend to become fact...or should I say FAQ. Also, pretty much all 410's are set up half decently from the factory. Where-as all of the 529/571's were set by some shop or a beer drinkin' buddy, and more times than not, they were set up poorly. Even with the so-called 'professional shops', there is no guarantee that it was done right. So, as a result, we tend to hear about more 529/571 breakages.

One of the biggest killers of ring/pinions in general is ring deflections. As the ring deflects away from the pinion (due to higher torque loads or loose bearings), the contact point dynamically moves to the outside edge of the ring's tooth and then BAM...one less ring tooth. How to minimize the ring deflections?....just tighten the carrier bearings to about the 100 foot/pound marker. Sounds easy but rarely done. Other items that lead to long life......high qual gears like PRECISION......solid collars.....spot on contact pattern....and synthetic oil if the highway or towing is involved.