(23 low res pics loading)

DEC 21 2004

I marked and removed the carrier bearing caps...

I employed 2 tire irons to EASILY remove the carrier.

The carrier bearing shims are on the outside...each side measured about .111". These are really stout shims which is good.

The yoke was a tight fit onto the pinion so I used the ole 10 ton press and the pinion effortlessly dropped out.

This old bearing separator has been thru quite a bit and has removed many a pinion bearing with Zero damage report. The bearing cages usually make strong contact with the dish surface on the separators.....the key to no damage is to modify the dish. I use a worn down grinding wheel and it works great. I purchased my separator from JC Whitney years ago.

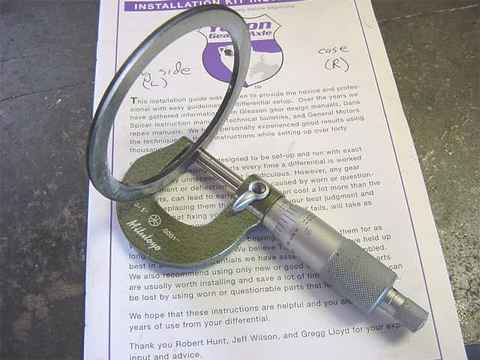

This is my IFS third and my wheelin' with this rig is mainly camping and exploring so I am re-using the bearings....as long as they check out good. I safely removed the big pinion bearing and, as seen in the pic, measured the factory pinion shim at .0995". It's nice to have vernier micrometers......and even nicer to have a camera that will get as close as 1 inch.

This main pinion bearing to be transferred over to the 571 pinion.

The Motive ring gear appeared to have very good quality and had these marking...V T571 IFS 40x7 M 10/00

I pressed the original pinion bearing on with the .0995 shim.

This is the mini-kit I received from Superior Gear. The only thing I really needed from it was the crush sleeve and it was the correct fit...unlike the pinion nut shown in the kit which was way too big.

I re-assembled it without the crush and used the old pinion nut and set the pre-load for about 10 in/lb. I made sure that I had lotsa gear oil on the pinion bearings to give smooth accurate readings. This "torque wrench" is another cheap investment and is available from some bicycle shops for 40 smackaroos.

I have heard reports of some having extreme difficulty removing the old ring gear...I don't understand unless they forgot to take the bolts out!

18 alternating light taps with the chisel and hammer and the ring dropped off.

Sometime I wonder how flat my file really is...but I still run it around the ring gear to check/file the high spots.

What is this thing about putting the ring in boiling water/oil to 'help' it go onto the carrier easier? I just line it up by eyeball and use 2 of the bolts to pull it on all the way.

There was some carrier bearing pre-load I noted as I pulled the carrier out with the tire irons....it will need more during the final set but for the purposes of checking the first pattern I will use just the .111" shims. Nobody seems to supply any carrier bearing shimming in their kits but as it turns out, the shims used on Dana44/60 applications behind the big pinion bearing race are the correct diameter for IFS Toyota carrier bearings.

The carrier dropped in nicely with a piece of wood and a hammer seating the bearings. Having a dial indicator with magnetic base is a cheap investment and a must have for setting backlash. I think Harbor freight has the combo for 25 bucks or less.

Lucky me. The factory shim nailed it right on. I am noting in the pic how easy it is to wiggle the ring gear within the backlash range. That means the carrier bearing pre-load could be alot tighter. Tight CB pre-load keeps the ring from deflecting under heavy loads.

close-up of the drive side.

the coast side....

See this casting right here.....

Well, due to the extreme thickness of the 571 ratio, the teeth come very very close to scrapping. I measured less than .003" with my feeler gauges.

I had to take the carrier out again anyways to put the crush sleeve in so it was a good opportunity to 'clearance' it some with the grinder. I also took the opportunity to also add 7 thou to the ring gear side on the carrier bearing shim and 3.5 thou on the other side. It was more difficult to get the carrier to seat down but it did happen.

Might be my imagination but the carrier bearings look to be 'locked in place' and don't have a chance of moving......at least compared to the stronger 8" rear 3rd which has raised towers that can flex a little. This would help the over-all strength of the smaller IFS ring/pinion set-up.....this is assuming the carrier bearings are shimmed extra tight like mine are here. I believe that this 571 install to be much stronger than the little axles that slide into the side-gears (27 spline and 1.075" diameter). If anything happens it's because the lower 571 ratio will introduce 33% more torque or strain on the axles/CV's so now maybe a CV will explode. But then again, this is a 22RE with an automatic so maybe everything will last for years.